Abstract

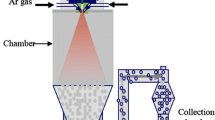

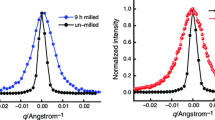

Nanocrystalline iron-oxide powder was fabricated with an inert gas condensation (IGC) method combined with evaporation, and in-situ oxidation techniques. The particle size of iron-oxide powder was controlled by varying the helium gas pressure between 0.1 and 10 Torr, with the smallest one =10 nm at 0.1 Torr. The nanostructure was characterized by TEM. Nanocrystalline iron-oxide powder was sintered with the pulse electric current sintering (PECS) method to obtain densified γ-Fe2O3 materials, and suitably densified nano-grained γ-Fe2O3 materials (≈ 40 nm) of great hardness were obtained. The correlation between the nanostructure and magnetic properties of nanocrystalline powder and densified γ-Fe2O3 materials was also investigated.

Similar content being viewed by others

References

H. Gleiter.Prog. in Mater. Sci. 4, 33 (1990).

R. Uyeda,Prog. in Mater. Sci. 5, 15 (1991).

R. W. Siegel and G. E. Fougere,Nanostuct. Mater. 6, 205 (1995).

F. Wakai, S. Sakaguchi and Y. Matsuno,Adv. Ceram. Mater. 1, 259 (1986).

T. G. Nieh and J. Wadsworth,Acta metall. 38, I 121 (1990).

T. Yamamoto, R. D. Shull and H. W. Hahn,Nanostruct. Mater. 9, 539 (1997).

G. Skandan and B. H. Kear,Mater. Sci. Forum 243-245, 217 (1997).

N. Tamari, T. Tanaka, K. Tanakla, I. Kondoh, M. Kawahara and M. Tokita,J. Ceram. Soc. Jpn. 103 740 (1995).

I. Kondoh, T. Tanaka, and N. Tamari,J. Ceram. Soc. Jpn. 102, 505 (1994).

Y. H. Choa, H. Kawaoka, T. Sekino, and K. Niihara,Key Eng. Mater. 132-133, 2009 (1997).

T. Yamamoto, R. D. Shull, P. R. Bandaru, F. Cosandey, and H. W. Hahn,Jpn. J. Appl. Phys. 33, L1301 (1994).

T. Nakayama, T. A. Yamamoto, Y. H. Choa, and K. Niihara,Key Eng. Mater. 161-163 497 (1998).

T. Yamakuchi and H. Yanakida,in Magneto Ceramics, Ceramics Science Series 4, p. 178, Gibouto Pub. Com. (1985).

B. D. Cullity, inElements of X-ray Diffraction, 2nd Edition, p. 102, Addison-Wesley Pub. Com. Inc. (1984).

I. J. McColm, inCeramic Hardness, p. 282, Plenum Pub. Corp. (1990).

H. Hahn and K. A. Padmanabhan,NanoStruct. Mater. 6 191 (1995).

T. Yamakuchi and H. Yanakida, inMagneto Ceramics, Ceramics Science Series 4, p. 231, Gibouto Pub. Com. (1985).

J. E. Knowles,IEEE Trans. Mag. MAG-16, 62 (1980).

S. Tochihara, and Y Imaoka,IEEE Trans. Mag. MAG-6, 808 (1973).

T. Yamakuchi and H. Yanakida, inMagneto Ceramics, Ceramics Science Series 4, p. 241, Gibouto Pub. Com. (1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Choa, YH., Nakayama, T., Sekino, T. et al. Synthesis and mechanical/magnetic properties of nano-grained iron-oxides prepared with an inert gas condensation and pulse electric current sintering process. Metals and Materials 5, 135–139 (1999). https://doi.org/10.1007/BF03026043

Issue Date:

DOI: https://doi.org/10.1007/BF03026043